Energy

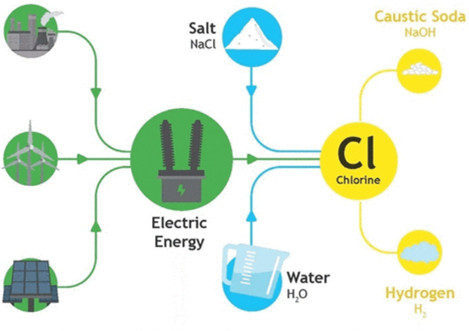

Electricity is essential for the chlor-alkali industry

Commercial production of chlor-alkali products is a large-scale, round-the-clock process that uses electricity as a raw material. Therefore, a reliable electricity supply is essential. Not only chlor-alkali plants, but also numerous other manufacturing industries that require chlor-alkali supplies, are unable to operate when there is a risk of power outages.

Chlorine production is an energy intensive process

Chlor-alkali production is energy intensive: 50-70% of the variable cost related to making chlorine is due to electricity (see further information in this document). Operators are therefore sensitive to electricity price trends. Without secure and competitively priced electricity supplies, Europe will no longer be an attractive location for future investments. Chlor-alkali -based production will risk moving elsewhere, together with other manufacturing operations and jobs.

Euro Chlor supports all attempts to reduce the carbon content of electricity and is keen to work with policy makers and planners to help shape an energy policy that ensures sustainable, reliable and competitively priced electricity. However, this is not just a challenge for our industry. All European Energy Intensive Industries (EII) are impacted by the changing face of energy on the continent.

Towards a low carbon economy

Within the 2030 Framework for climate and energy, the EU has set targets and policy objectives for the period of 2020 to 2030. These targets aim to help the EU achieve a more competitive, secure and sustainable energy system and a reduction of greenhouse gas (GHG) emissions by 80-95% when compared to 1990 levels by 2050. To achieve this, significant investments will be needed in new low-carbon technologies, renewable energy, energy efficiency, and grid infrastructure. Specific targets for 2030 are:

- A 40% cut in GHG emissions compared to 1990 levels

- At least a 32% share of renewable energy consumption

- Indicative target for an improvement in energy efficiency at EU level of at least 32.5% (compared to projections), to be reviewed by 2023, together with the renewable energy target. These targets can only be raised, not lowered.

- Support the completion of the internal energy market by achieving the existing electricity interconnection target of 10% by 2020, with a view to reaching 15% by 2030

See here how chlor-alkali chemistry is essential in the production and efficient use of energy

Challenges to overcome

To achieve the above targets, the main challenges for the chlor-alkali industry are investigating:

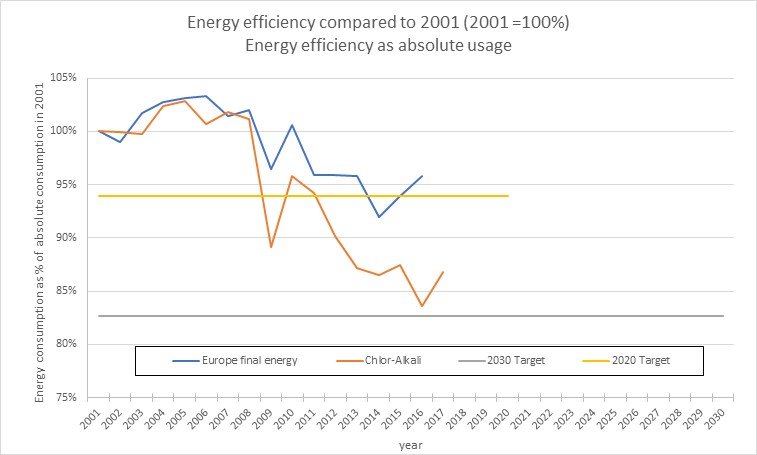

1) Energy efficiency

To increase energy efficiency by 32.5% by 2030. The agreed objective for an EU of 28 Member States was to contain energy consumption below 1,273 Mtoe (million tons of oil equivalents) of primary energy consumption and no more than 956 Mtoe of final energy consumption. The chlor-alkali industry does quite well compared to the European requirement, as can be seen in this graph based on our annual sustainability review data.

Note: Data comes from the energy consumption and yearly production figures of Euro Chlor members. Electricity consumption is converted with 42% efficiency to primary energy and steam consumption with 90% efficiency.

2) Decarbonising and reducing CO2

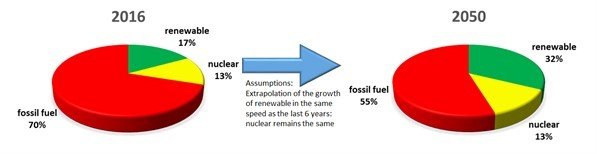

Europe want to increase the share of renewables to 32% by 2030. The next more ambitious goal for 2050 aims for a (net) zero or even negative GHG emissions in Europe. The challenges for Europe to reach these goals are presented extensively in our Energy Dossier. As part of this, the figure below illustrates the gap between the 2016 energy supply mix and an extrapolation to the future (2050).

- The red slice represents potential ‘missing energy’, if conventional fossil fuel generation has to be phased out. The green part represents renewable energy production, assuming the same growth rate for wind and solar of recent years is maintained until 2050.

- The yellow part represents ‘nuclear’, which could fill the gap. However, as nuclear energy is under political pressure in some EU countries, it could also remain constant or even reduce, further widening the gap.

As an energy intensive process, the industry’s health and future growth in Europe is dependent on access to reliable and affordable electricity supplies. The low-carbon future we are working towards involves intense efforts combined with innovative technologies to produce energy and/or electricity. Current energy technology developments have limitations so, as well as liaising with our members and key stakeholders to figure out how the ambitious renewable targets could be achieved, Euro Chlor is investigating innovative energy solutions to find a European equivalent to the US cheap ‘shale gas’, for example. This work includes exploring alternatives to low carbon energy and/or electricity other than wind and solar such as traditional nuclear reactors (uranium) and innovative nuclear reactors (e.g. molten salt reactors based on thorium).

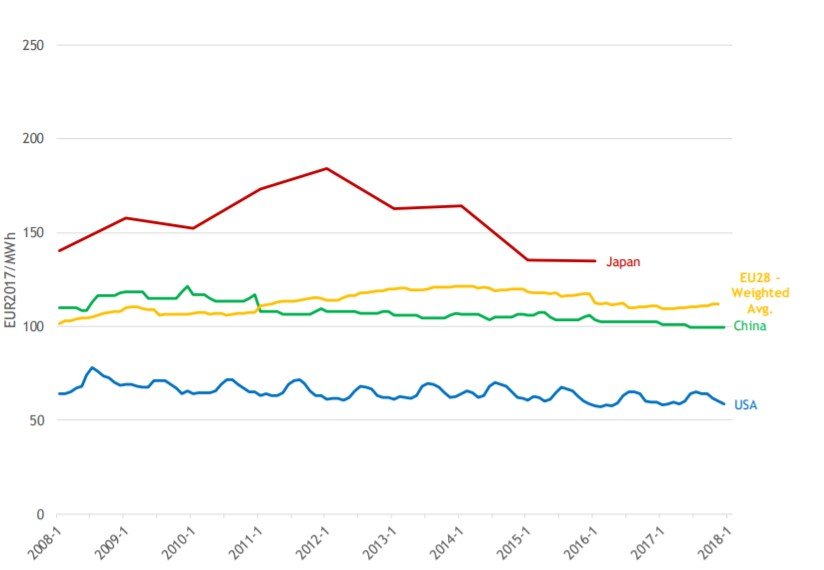

Reliable and competitive pricing might be at risk due to the required changes for a low carbon society as set out in the EU’s recent long-term vision for a prosperous, modern, competitive and climate neutral economy. A divergence in electricity prices within Europe and between Europe and other regions, or the possibility of an increasing frequency of interruptions to supply, will put jobs and investment at risk.

A 2019 European Commission report shows the average figures for industrial users. There are significant differences in prices between countries, which need to be taken into consideration when discussing the competitiveness of European industry.

- Retail electricity prices for industry – Sources: Eurostat, CEIC and IEA

Managing electricity supply is complex and needs to strike a balance between reducing the environmental impact, delivering at competitive prices and safeguarding reliability. Realistically the future will combine different options, with additional benefits delivered through technical innovation, improved interconnection, energy storage and consumption management.

The industry gets compensations for higher electricity prices through indirect CO2 compensations on state level, and this needs to remain the case for the future. However, only 10 of the 28 Member States use this option and not all at the same level and other mechanisms exist. Euro Chlor is striving for equal compensation for all our members, as well as raising indirect compensation to the maximum level aligned to direct compensation.

3) Hydrogen and Power-to-Gas

Hydrogen has long been used by the chemical industry as a feedstock in industrial processes and is seen today as a major contributor to a fully decarbonised energy system. Hydrogen can potentially contribute to the decarbonisation of various sectors: as storage in the power sector, as an energy carrier option used in heating, transport and industry and finally as a feedstock for industries as steel, chemicals and e-fuels.

Power-to-Gas technologies refer to technologies that enable electricity to be transformed into synthetic gases (hydrogen, methane or other gases) and liquids. Hydrogen produced with carbon-free electricity combined with CO2 from a sustainable source or Direct Air Capture can make a carbon-neutral alternative to natural gas or oil, and thus can be distributed via existing transmission/distribution system and used by existing installations and applications. These technologies become attractive in the context of abundant electricity generated from carbon-free sources (renewables and nuclear). The drawback is that their production is energy-intensive.

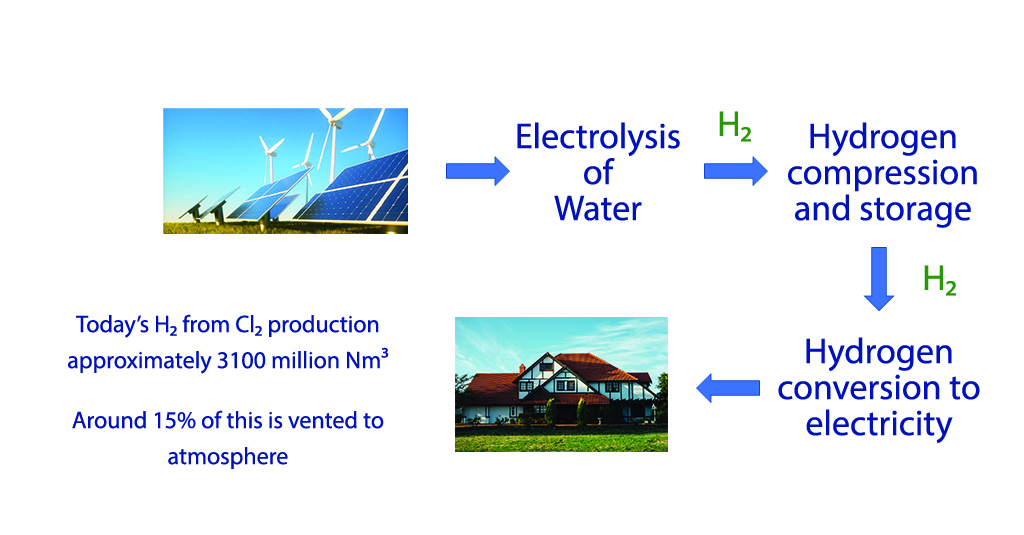

Hydrogen is a by-product of chlor-alkali production and therefore our industry can play a leading role in this aspect. We are exploring opportunities to use hydrogen in our communities, transportation and the generation of energy. Here is theoretically how this could work:

From electricity to hydrogen (and back…?)

This includes investigating the option to produce hydrogen out of water and low carbon electricity to act as energy carrier, energy storage or as building block for chemicals, based on hydrogen and CO2 as part of our contribution to the carbon neutral society of the future.